- Petrocertif Construction Academy Newsletter

- Posts

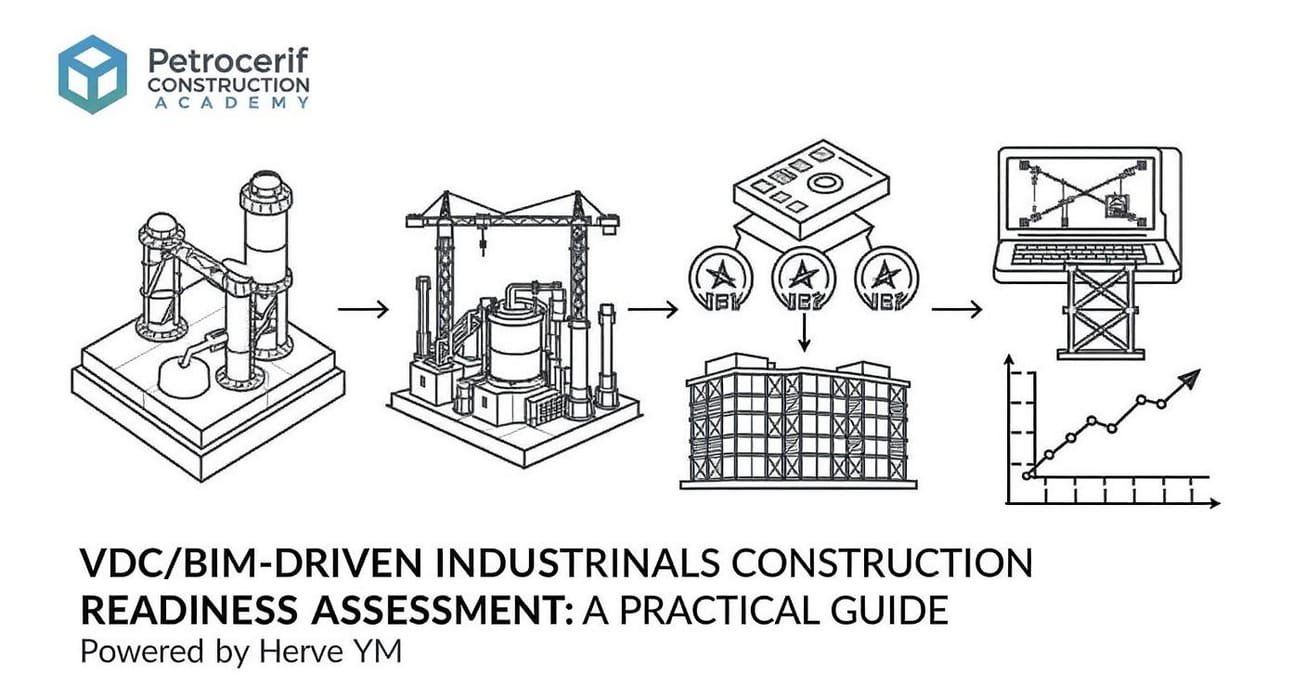

- VDC/BIM-DRIVEN INDUSTRIALS CONSTRUCTION READINESS ASSESSMENT A PRACTICAL GUIDE

VDC/BIM-DRIVEN INDUSTRIALS CONSTRUCTION READINESS ASSESSMENT A PRACTICAL GUIDE

The industrial construction sector, characterized by its complexity, stringent regulations, and high capital expenditure, is undergoing a profound transformation. At the forefront of this evolution are Virtual Design and Construction (VDC) and Building Information Modeling (BIM). This guide, drawing upon best practices and critical insights, outlines a methodology for leveraging VDC and BIM to conduct robust industrial construction readiness assessments, ensuring project success from conception to completion.

Introduction to VDC and BIM

Virtual Design and Construction (VDC) and Building Information Modeling (BIM) are revolutionary methodologies that have reshaped how industrial construction projects are designed, executed, and delivered. VDC involves the multidisciplinary integration of digital models and processes to plan, design, and manage construction workflows virtually before breaking ground. BIM, a key component of VDC, involves creating intelligent 3D models that serve as centralized sources of data throughout the project lifecycle (CIOB, 2022).

In industrial construction where high-risk activities, large-scale equipment, and compliance-bound environments dominate, the integration of VDC/BIM is not just valuable but necessary. It supports better coordination, clearer visibility, and a data-rich approach to predict project outcomes.

In the context of Africa’s rapidly growing industrial sector, where infrastructure investments are projected to reach $180 billion annually by 2030 (African Development Bank, 2023), VDC and BIM address the region’s unique challenges, such as resource constraints and fragmented project delivery. By aligning design, procurement, and execution, these tools enhance construction readiness, ensuring projects meet stringent timelines and sustainability goals.

The relevance of VDC/BIM in industrial projects stems from their ability to integrate design, procurement, and construction phases into a cohesive digital workflow. According to the Chartered Institute of Building (CIOB, 2020), digital construction methods can reduce project delays by up to 20% and cost overruns by 15%.

Conceptual Framework: Integrating VDC/BIM with Construction Readiness

VDC and BIM serve as enablers of construction readiness when integrated with frameworks such as Valency Inc.'s Construction Readiness Assessment Model and the Construction Industry Institute (CII) IR 340-2. They provide a digital thread from design to handover, fostering early identification of issues and promoting real-time collaboration.

In the context of Africa's industrialization ambitions including energy infrastructure, manufacturing, and mining a VDC/BIM-driven approach represents a leap forward toward modern, tech-enabled project delivery, especially in greenfield and brownfield settings.

As African nations pursue ambitious infrastructure and industrial development goals, adopting VDC/BIM-driven readiness assessments becomes paramount for de-risking investments, attracting foreign capital, and fostering sustainable growth (CMAA, n.d.).

Construction readiness refers to the preparedness of a project before breaking ground, ensuring that design, logistics, and execution risks are minimized. VDC and BIM contribute by:

Enabling Digital Twins: Virtual prototypes allow stakeholders to assess constructability before physical work begins (Valency, 2023).

Supporting Decision-Making: Real-time clash detection and 4D/5D simulations optimize scheduling and cost estimation (CMMA, 2022).

In Africa, where infrastructure gaps persist, VDC/BIM adoption can accelerate industrialization by improving project feasibility and reducing reliance on fragmented traditional methods.

Personal Reflection: From my experience, managing the Grand Ethiopian Renaissance Dam (GERDP), VDC’s ability to simulate workflows and BIM’s data integration were pivotal in identifying bottlenecks early, reducing an 8-month delay within four months. This underscores the need for a structured readiness framework that leverages digital tools to align stakeholders and optimize resources, particularly in resource-constrained environments like Africa.

Construction Readiness Metrics

Effective construction readiness hinges on a clear set of critical readiness indicators. VDC and BIM provide invaluable insights into these metrics:

Design Documentation Completeness and Accuracy: Completeness and accuracy of design models, validated through BIM clash detection (e.g., Navisworks). Incomplete designs account for 20% of construction delays globally (Autodesk, 2022).

Automated clash detection in BIM platforms significantly reduces rework (Eastman et al., 2011).

Procurement Status: By linking BIM elements to procurement schedules and databases, project teams can track the readiness of long-lead items, critical equipment, and bulk materials. VDC facilitates the visualization of material flow and storage requirements, optimizing logistics.

Workforce Availability and Training: While not directly managed by BIM, VDC principles support the development of detailed execution plans that inform workforce planning. Simulation of complex installations can identify specific skill gaps and training needs.

Scheduling and Sequencing: BIM-enabled 4D modeling (3D model + time) visually represents the construction sequence, allowing for optimization of schedules, identification of potential bottlenecks, and communication of the plan to all stakeholders (Ku et al., 2011).

Constructability Analysis: This is where VDC and BIM truly shine. By simulating construction processes, teams can identify accessibility issues, complex lifting requirements, and potential safety hazards, offering early warnings and performance insights that prevent costly field changes.

Key readiness indicators where VDC/BIM provide value include:

METRIC | VDC/BIM CONTRIBUTION |

Design Documentation | Ensures completeness and clash-free models before construction. |

Procurement | Links BIM data to material tracking, reducing shortages. |

Workforce Planning | Simulates labor needs via 4D scheduling. |

Constructability Analysis | Identifies fabrication and assembly constraints early. |

VDC and BIM provide early warnings by visualizing performance metrics in real time. For instance, Valency’s VDC platforms enable stakeholders to monitor readiness indicators through dashboards, reducing cost overruns by up to 15% (Valency Inc., 2023).

Personal Reflection: Constructability analysis, a cornerstone of my work on hydraulic steel structures, relies on BIM to simulate assembly sequences. This proactive approach mitigates risks that traditional methods overlook, ensuring alignment with CMAA’s standards for project excellence (CMAA, 2022).

Digital Twin & Simulation Use Cases

The power of VDC and BIM is profoundly realized through the creation and utilization of digital twins and simulations. A digital twin, in this context, is a virtual replica of the proposed industrial facility, continuously updated with real-time project data. Before breaking ground, VDC and BIM facilitate:

Pre-construction Condition Simulation: Teams can simulate various construction scenarios, such as temporary works, crane placements, logistics routes, and even weather impacts, to validate plans and optimize site layout.

Virtual Mock-ups and Walkthroughs: Stakeholders, including operations and maintenance teams, can virtually "walk through" the facility, providing critical feedback on ergonomics, maintainability, and operational efficiency long before physical construction.

Process Simulation: For complex industrial processes, BIM can be integrated with process simulation software to optimize equipment layout, material flow, and even energy consumption, informing design decisions that influence operational readiness.

Decision-Making Support: By running multiple simulations under different parameters (e.g., resource availability, schedule variations), project managers can make informed decisions about resource allocation, risk mitigation strategies, and alternative construction methods.

Use Case: In a greenfield LNG plant, a BIM-driven digital twin simulated crane operations and material staging, identifying spatial constraints that saved $2 million in rework costs. This aligns with CIOB’s advocacy for digital tools to enhance project predictability (CIOB, 2021).

Personal Reflection: My work on the Nalubaale/Kira HPPS project used BIM simulations to optimize hydraulic steel structure installations, reducing on-site adjustments by 25%. Digital twins empower decision-makers to foresee challenges, a critical advantage in Africa’s fast-paced industrial growth.

Risk Mitigation & Predictive Planning

VDC and BIM mitigate risks by identifying constructability issues and enabling data-driven planning. BIM’s parametric models detect clashes (e.g., piping vs. structural elements), reducing rework by 10-20% (Autodesk, 2022). Predictive planning leverages BIM data to forecast risks, such as material shortages or labor inefficiencies, using AI algorithms.

VDC/BIM enhances risk management through:

Constructability Audits: Automated clash detection in BIM models prevents field conflicts.

Predictive Analytics: Historical BIM data forecasts schedule deviations using AI (Eastman et al., 2011).

A study by CMMA (2022) found that BIM-driven risk assessments reduce unplanned costs by 12-18%.

Personal Reflection: In the GERDP project, BIM-driven risk analysis identified misaligned procurement schedules, enabling corrective actions that saved four months.

This reinforces the need for predictive tools to manage Africa’s complex industrial projects, where stakeholder misalignment is common.

Implementation Strategy

Implementing a VDC and BIM-driven assessment requires a structured approach and strategic integration with existing project management tools.

Steps to Apply a VDC and BIM-Driven Assessment:

Define Project Goals and KPIs: Clearly articulate what constitutes "readiness" for the specific industrial project, aligning with overall business objectives.

Establish BIM Execution Plan (BEP): Develop a comprehensive BEP outlining BIM uses, information requirements, collaboration protocols, and technology platforms.

Integrate Design and Construction Teams: Foster early and continuous collaboration between design, engineering, and construction teams, leveraging VDC principles from conceptual design.

Develop Digital Twin: Build a robust digital twin of the facility, incorporating all relevant models and data.

Conduct Iterative Simulations and Reviews: Regularly perform 4D and 5D simulations, clash detection, constructability reviews, and virtual walkthroughs.

Track Readiness Metrics: Use the insights gained from VDC/BIM to continuously monitor and report on the critical readiness indicators defined in section 3.

Implement Feedback Loops: Establish mechanisms for incorporating lessons learned from simulations and reviews back into the design and planning process.

With VDC/BIM-Driven Assessment:

Phase 1 (Design & Engineering): A comprehensive BIM model is developed, encompassing architectural, structural, MEP, and process piping. Automated clash detection identifies hundreds of clashes between disciplines, resolved in the design phase, saving millions in potential rework.

Phase 2 (Procurement & Logistics): 4D simulations visualize the delivery and installation sequence of long-lead items like reaction vessels and distillation columns. This highlights potential access constraints and informs the layout of temporary storage areas and crane paths. The digital twin tracks the real-time location and status of procured components, providing an accurate readiness picture.

Phase 3 (Construction Readiness): Virtual walkthroughs with the operations team identify ergonomic issues around valve clusters and maintenance access points, leading to design modifications before fabrication. 5D simulations provide accurate cost forecasts based on the refined models, enabling precise budget control. Safety simulations identify potential fall hazards during equipment installation, allowing for the pre-planning of safety measures and scaffolding.

Outcome: The project experiences significantly fewer RFI's, reduced schedule delays, and a safer construction environment, ultimately delivering the facility on time and within budget, with enhanced operational readiness.

Greenfield vs. Brownfield Projects

Greenfield: VDC and BIM facilitate optimal site planning and resource allocation.

Brownfield: Digital models assist in retrofitting and upgrading existing infrastructure.

Challenges & Limitations

Despite the immense benefits, implementing VDC/BIM-driven readiness assessments comes with inherent challenges:

Data Interoperability: Different software platforms and disciplines often use varying data formats, leading to challenges in seamless data exchange and integration. Standardization efforts are ongoing but require consistent adoption. Requiring standardized protocols like ISO 19650 (ISO, 2020).

Change Management: Shifting from traditional workflows to VDC/BIM-centric processes requires significant organizational change, including new roles, responsibilities, and mindsets. Resistance to change can be a major hurdle.

Stakeholder Alignment: Ensuring all project stakeholders—owners, designers, contractors, and suppliers are aligned on the VDC/BIM vision, data requirements, and collaborative processes is crucial for success.

Lack of buy-in from any key party can undermine the effort.

Initial Investment: The upfront investment in software, hardware, and training can be substantial, though the long-term ROI is typically very high.

Skill Gaps: A shortage of skilled VDC/BIM professionals can impede effective implementation.

Personal Reflection: In my work, stakeholder misalignment often stemmed from poor communication. VDC’s collaborative platforms mitigated this, but upskilling remains critical to overcome resistance in traditional construction cultures.